Last news about IDEKO.

The technology centre had a prominent presence at the seminars organised by the machine tool manufacturer to publicise its new range of gantry machines for the machining of large workpieces.

The research body has collaborated with the firm from Guipúzcoa in the development of solutions for cancelling vibrations and measurement systems for the alignment of workpieces.

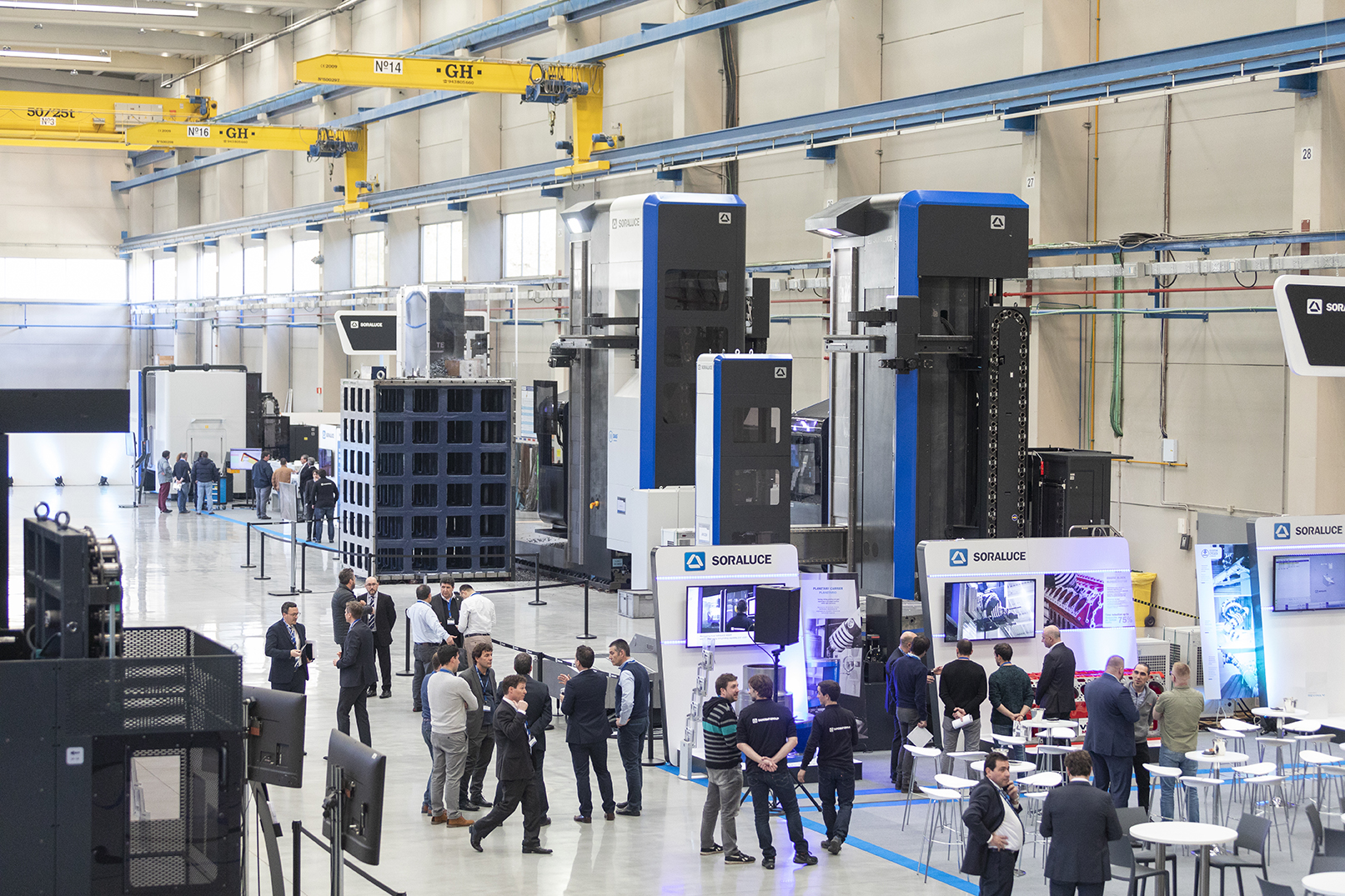

The SORALUCE PORTAL SUMMIT event was held from 20 to 22 March at the new production plant that the Basque cooperative has constructed in Bergara.

The Basque technology centre IK4-IDEKO had a prominent presence at the SORALUCE PORTAL SUMMIT event, which the machine tool manufacturer held in Bergara between 20 and 22 March. At the event, the research body exhibited damping solutions and advanced systems for the alignment of workpieces in the machines.

"One of our principal objectives is to generate scientific knowledge in the field of advanced manufacture in order to transfer it to the industrial sector, and provide companies with technological solutions with an innovative and differentiating approach that will allow them to better position themselves in the market and boost their competitiveness", said the managing director of IK4-IDEKO, Nerea Aranguren.

In this context, the body has worked together with the company SORALUCE in the development of technologically advanced solutions which have responded to specific problems generated during the manufacturing processes.

Specifically, the collaboration between the researchers of the Dynamics and control research group of IK4-IDEKO and SORALUCE has resulted in the development of the active damping systems DAS+ and DWS (Dynamics Workpiece Stabiliser), solutions that make it possible to eliminate self-excited vibrations and chatter.

Specifically, the systems, developed by IK4-IDEKO and exhibited at the event, yield a productivity increase of some 300% and a cutting capacity of 100 % over the entire volume of the workpiece.

Also on display at the event was the 3D VSET measuring system, another development resulting from the alliance between SORALUCE and IK4-IDEKO. This development, led by the Design and Precision Engineering research group, is a solution that reduces the blank alignment process time and ensures a fast and safe execution of the measuring and fitting phases. The measuring system, based on 3D technology, makes it possible to convert the data collected in two dimensions into information in 3D , by means of reconstruction software of its own development that is incorporated into a controller.

"These developments are clear reflections of our commitment to technology transfer and our closeness to companies. They started as R&D projects that take their first steps in the laboratory and end up integrated into the products and services range that SORALUCE offers to its customers", added Aranguren.

The SORALUCE SUMMIT 2019 event organised to promote the exchange of knowledge between professionals and companies of the industrial manufacturing sector was held in the Portal Factory, the new production plant that the machine tool manufacturer has built in the town of Bergara in Guipúzcoa.

The facility, which is at full capacity, is designed for the manufacture of a new range of large and high-power gantry machines for the machining of large workpieces.