4 Research Lines, key factors in the development of our specialization industrial production and manufacturing technologies.

The specialised research line in design and precision engineering focuses on the development of prototypes, mechanisms, structures, modelling and simulation of components, as well as on the analysis of energy consumption of machine tools.

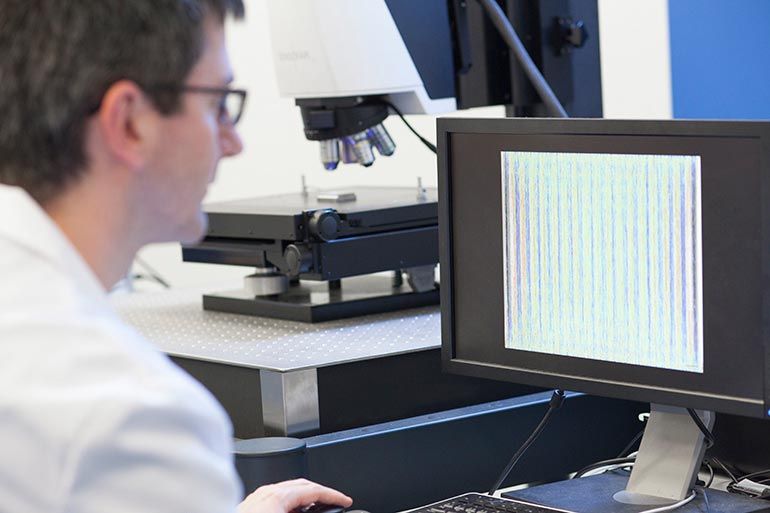

The researchers of this line of research also carry out behavioural studies of precision of equipment, mainly in relation to thermal effects and geometrical errors. This task is performed through experimental observation of compensation on the machine, the development of high-dynamics precision systems and calibration equipment.

The department also performs fine-tuning of compensation models for volumetric calibration, hydrostatic and hydrodynamic lubrication, analysis of the life cycle of machines and ecological efficiency.

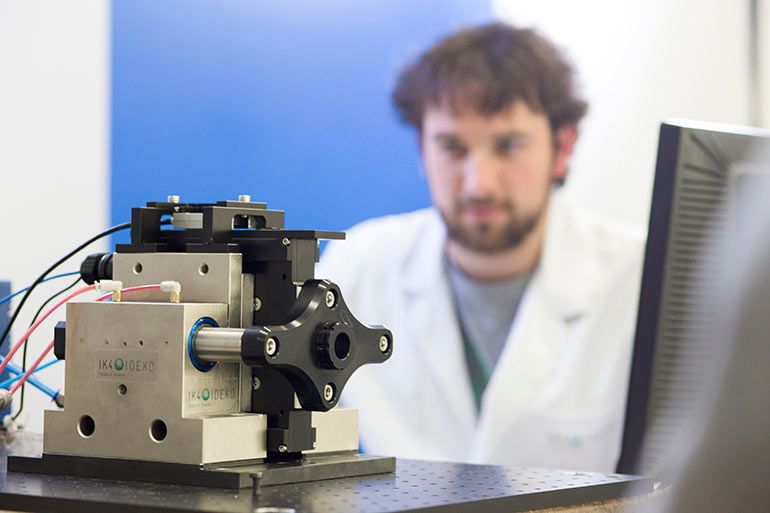

The technical team of Design and Precision Engineering is responsible for the development of machines, systems and manufacturing processes for precision parts.

In particular, it deals with clamping systems, handling and manufacturing processes, design and development of ultra-precision devices and compensation systems for both errors in volume and caused by heat. All these fields of action are oriented to achieve ultra precision levels.

Because of the methodology and the knowledge of the researchers of this research line, high precision manufacturing technology has been developed to support the design and geometric and functional validation of new machines. Several prototypes have been built that have become milestones at both national and international level.

The Design and Precision Engineering line works on research projects related to new concepts of mechanisms where precision is of paramount importance. It tackles the complete design cycle that includes drawing up specifications, conception and architecture of the mechanism, design and simulation of behaviour with static, dynamic, thermal and multiphysics calculations, and finally the prototype phase and experimental characterisation.

During the experimental phase of improved accuracy, work on forecasting and compensation models of thermal behaviour of machines is performed, as well as on volumetric calibration of machine geometrical errors caused by thermal and gravitational effects.

Development of technologies and solutions in the design of mechanisms and high-precision machines.

Advanced Concepts of machines and components:

Advanced mechanical and thermal simulations of behaviour of all kinds of systems.

Ecodesign of machines.