Last news about IDEKO.

Last 11 March, the Design and Precision Engineering researcher from the research centre, Beñat Iñigo Ibabe, presented a study on the calibration and machine tool compensation procedures based on digital twins

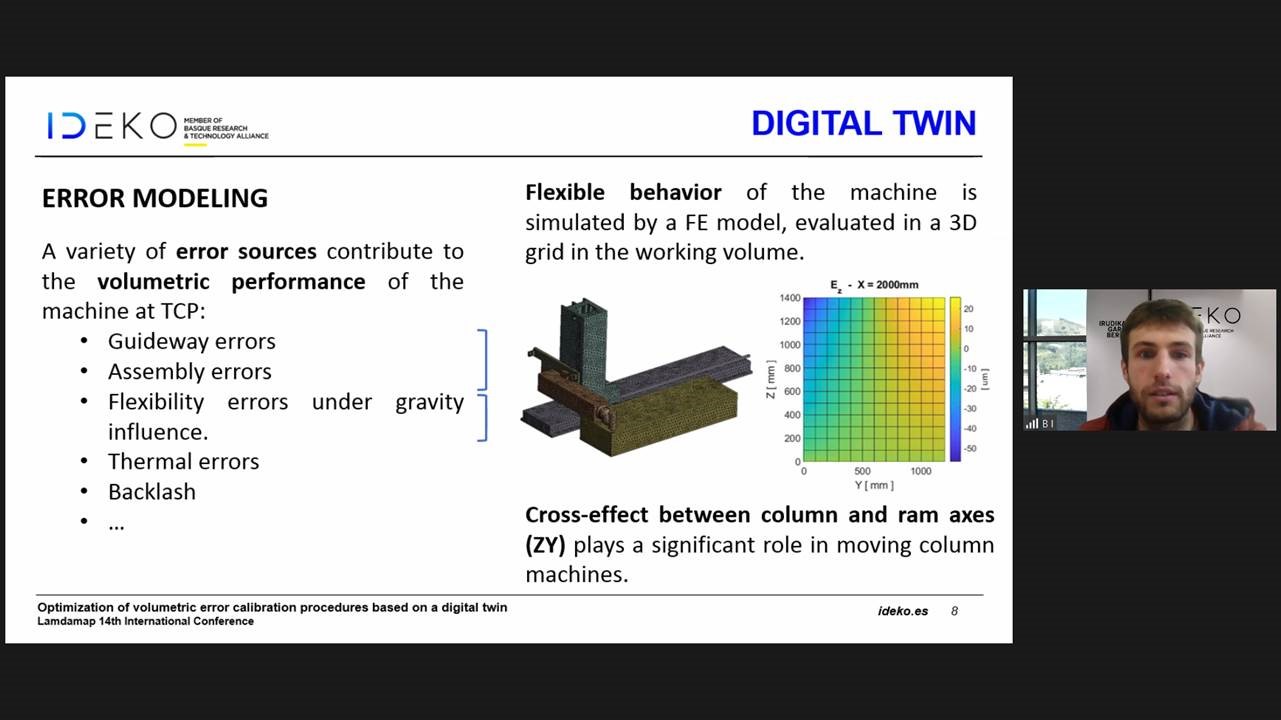

The developments derived from information and communication technologies such as digital twins, allows real time monitoring of the machinery during its entire useful life. These systems are becoming very important in industrial manufacturing and especially in the field of equipment errors and volumetric accuracy, as they allow rapid calibration and verification processes to be carried out.

The latest industry 4.0 innovations and trends linked to this field were the main highlights of the 14th Virtual Lamdamap international conference, an event organised by the Euspen association. Here the Design and Precision Engineering researcher from the IDEKO technology centre, Beñat Iñigo Ibabe, shared his research work on the optimisation of volumetric error calibration procedures based on a digital twin.

Specifically, Ibabe presented, via internet link, a work based on the measurement of calibrated artefacts within the work volume and focussed on extracting the information necessary on the precision of the machine. This optimisation study consists of a calibration and compensation procedure based on digital twin technology.

“We optimise various aspects of the calibration and compensation process in order to find the best measurement strategy for each application in accordance with volumetric criteria based on the performance” explained the researcher at the conference.

As a case study, he presented a 3-axis travelling column milling machine. The resulting calibration strategy represents a beneficial procedure as regards cost and time, critical aspects in the application of these solutions, which can be integrated into a machine tool.

The frequent repetition of these measurements allows the user or the manufacturer to monitor the volumetric performance of the machine on a day-to-day basis and take the corresponding preventive actions without affecting production.

The 14th Euspen International Conference, LAMDAMAP 2021, was planned to be held at the KTH Royal Institute of Technology in Sweden. However, due to the COVID-19 pandemic, it was decided to hold the meeting virtually, to ensure the participants remained connected in a safe way.>

The event was focused on aspects such as metrology in new manufacturing techniques, new developments in measurement techniques, new manufacturing and machine tool technologies, performance evaluation for machine tools and CMM, roughness and machine-tool standards, evaluation of the precision and performance of industrial manipulators, metrology integrated into new manufacturing techniques and automatic learning for metrology and precision.