Last news about IDEKO.

The research centre has a prominent presence at the forum that specialises in machine tools, held virtually on this occasion.

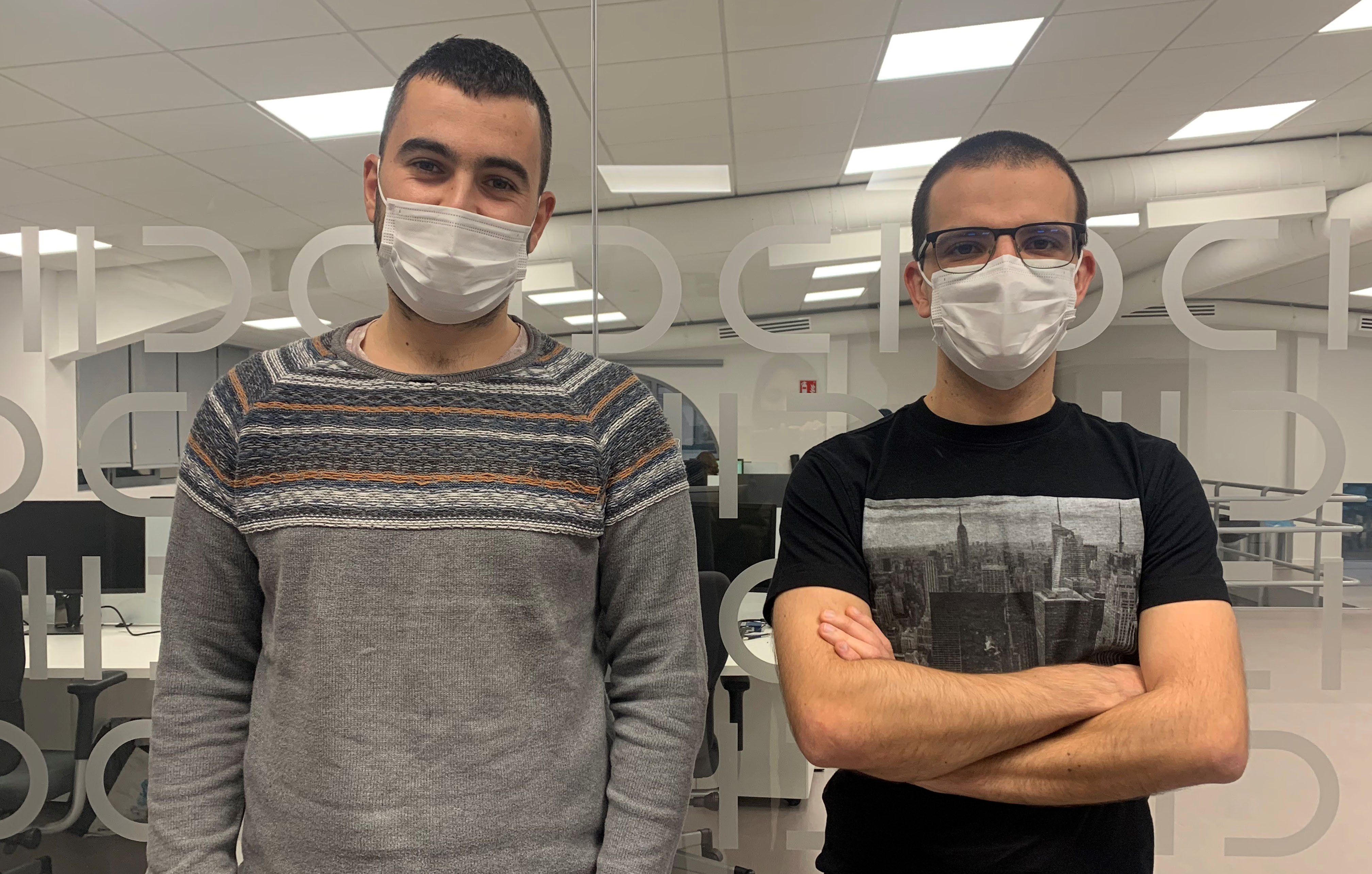

The researchers Markel Sanz and Iker Urresti are presenting their work for cancelling chatter and clean machining systems at the Congress, held from 9 to 11 December.

IDEKO's scientific director, Jokin Muñoa, is also a member of the event's scientific committee.

The IDEKO research centre will have a prominent presence at the 11th UTIS International Congress, which is being held between 9 and 11 December in virtual format. In addition to presenting their main innovations in machining dynamics and control, IDEKO forms part of the scientific committee of the forum that specialises in machine-tools.

Specifically, IDEKO's experts Markel Sanz are Iker Urresti are presenting at UTIS 2021 the results of their latest research on solutions for the elimination of chatter and clean machining systems. Also, IDEKO's scientific director, Jokin Muñoa, is also a member of the event's scientific committee.

On the one hand, the Dynamics and Control Group researcher, Markel Sanz, is presenting within the framework of the conference his work “Avoiding forced vibration in thin wall milling by tuning the radial engagement”, which involves developing a solution that seeks to increase productivity in thin-wall milling.

“Forced vibrations are one of the factors that limit productivity when milling thin walls. Their low rigidity and damping combine with a highly interrupted cut that, depending on the machining conditions, can lead to high amplitude vibrations”, explained Sanz.

By defining a simple unidirectional milling model, this work has studied the effect of radial engagement on the forced vibration during thin-wall milling independently from other dynamics or process parameters of the workpiece. In this way, it is demonstrated that up milling is superior to down milling in terms of forced vibration.

Furthermore,

Sanz's work demonstrates that even though fully eliminating the forced

vibration by tuning the engagement is impossible, it is possible to find an

engagement angle that results in a minimum forced vibration and that only

depends on the ratio of cutting forces and the number of milling cutter edges.

The results are finally validated with numerical simulations.

On the other hand, the engineer Iker Urresti of the Manufacturing Processes Research Group is presenting an internal chip suction system that guarantees a clean machining process in the presentation “Spindle and cutting tools for internal suction of chip and dust in CFRP trimming”.

“The elimination of the chips and dust generated during the edge finishing process of workpieces manufactured in carbon fibre reinforced polymers (CFRP) continues to be a significant challenge for the industry due to the hazard that it poses to the health of operators” said Urresti.

Thus, this work presents the design and manufacture of cutting tools and head that allow the internal suction of the generated dust, thus eliminating dust and chips in the working area.

Nevertheless, with the aim of guaranteeing a clean machining process, besides conventional aspects of edge finishing such as surface quality, tool wear or the productivity rate, others have to be considered such as the effectiveness of the suction system.

Consequently, IDEKO's engineers are presenting an experimental analysis for the optimisation of this process by analysing the effect of the cutting conditions on the surface quality of the work piece, as well as the suction capacity. In the end, the optimal cutting conditions were identified for achieving a clean process by eliminating 98.4% of the chips and dust generated.

The UTIS International Machining Congress is a specialist forum that brings together over these three days; machine tool manufacturers, toolmakers, experts in machining processes and representatives from various research centres and universities. The meetings, presentations, keynote speeches, visits to the stand and the stand area will be experienced through a virtual platform.

Subjects such as modelling machining operations, process stability analysis, cutting tool technologies and process optimisation, among others, are considered over these days. This event is also an international networking space that promotes synergies between attendees, collaboration as regards R&D and the implementation of innovative projects.