Last news about IDEKO.

The IDEKO research centre is participating in the Miraged programme that seeks to develop virtual replicas of equipment and processes to improve modelling, simulation and prediction solutions for production systems.

The project has the support of the Cervera programme led by the Centre for Technological and Industrial Development (CDTI), which is part of the Ministry of Science and Innovation.

The initiative is granting IDEKO the title of Cervera Centre of Excellence in Virtual Models and Digital Twins.

Forecasting the operation of a product, a machine or a production process before launch or even design and manufacture is an undeniable asset to determine if there are any errors and subsequently save costs.

In order to achieve this, it is key to focus on the development of modelling and simulation systems, an area that has undergone significant progress due to the boost of digital technologies.

This is the context in which the Miraged programme is being developed, an initiative that certifies IDEKO as a Cervera Centre of Excellence. It is part of the 2019 Aid Programme for Cervera Research Centres of Excellence, organised by the Ministry of Science and Innovation and backed by the Centre for Technological and Industrial Development (CDTI) with the aim of strengthening the role of applied research centres.

The research centre IDEKO, a member of the Basque Research and Technology Alliance (BRTA), is participating in this initiative that seeks to better prepare all entities involved in developing systems for modelling, simulating and predicting the behaviour of machines and manufacturing processes, through the creation of virtual models and digital twins for design and subsequent optimisation.

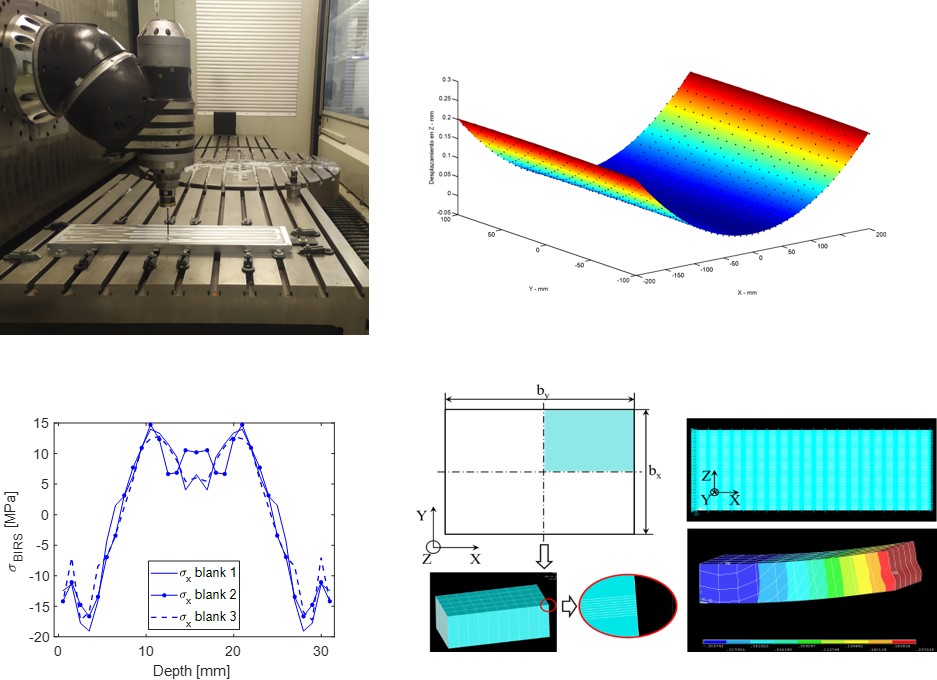

Three technical lines of action have been established within the working network. The first line of action concerns the creation of "virtual factories”, where simulation models will be developed to study the behaviour of manufacturing processes including hot forming, welding, machining, grinding, induction hardening and non-destructive inspection. The technical advances of the second line of research are aimed at predicting the onset of a failure in service, at models for predicting the propagation of cracks and the remaining life of the system, and at developing dynamic behaviour models. The third line focuses on integrating the models developed in the previous stages into digital twins.

In addition, the research centres will work on the training of researchers, in the dissemination of the results and on specific initiatives for promoting technology transfer to the industrial sector.

"Currently it is possible to generate a virtual replica of production systems capable of updating in real-time with real data from machines and processes. These virtual replicas are known as digital twins", said the person responsible for Miraged at IDEKO, Jose Luis Lanzagorta.

A digital twin is a digital replica of a product or process to which real-time data is incorporated that can be captured through sensors or Big-Data related technologies. Once this information is collected, it is processed with Artificial Intelligence, Cloud Computing and Machine Learning to produce a living twin on which improvements can be made and capabilities optimised.

“These solutions make it possible to analyse the reaction of a process to certain situations and improve its performance and efficiency. In addition, problems are detected before they occur, and as such they have a great potential for planning maintenance tasks, designing new, more efficient operating scenarios, developing new manufacturing plans or making future forecasts”, adds Lanzagorta.

Digital twins can provide additional data through digital sensorisation, generate synthetic data of the behaviour of the replicated system, determine the system status and life cycle, and facilitate decision-making in machine and system management based on artificial intelligence algorithms.

The main challenge for industry is to develop the capability to assimilate all these new technologies and incorporate them into its production processes. Hence, it would be possible to analyse a large amount of data and transform it into information that would substantiate decisions for optimising the process and increasing productivity.

The Miraged initiative, which will conclude in

2022, has a total budget of €3,190,249 and is geared towards this objective

through the strengthening of the capabilities of the research centres by means

of collaborative work and the boosting of their cooperation with companies in

order to respond to the challenges of an industry 4.0 environment.

An impetus to technology transfer

Specifically, IDEKO is pursuing its aim of achieving excellence in the development and subsequent transfer to business of technologies that can generate new manufacturing machines and processes that are more efficient, intelligent, accurate and environmentally friendly.

Within the framework of this initiative, IDEKO has identified a series of priority technical objectives such as the development of new advanced models that interact with the manufacturing process through the implementation of digital twins applicable to the production facility. These models and twins will be developed in the areas of expertise of the entity such as grinding, non-destructive inspection, distortion control and machine and process dynamics and control.

Another of the lines defined by the research centre in this project consists of promoting, extending and implementing high-impact technology actions that enable greater technology transfer to companies, and that stand out due to the quality of the scientific-technical research activity and strengthen the impact of collaborations with the production sector.

Likewise, the entity seeks to form part of an experience exchange and collaboration platform for the efficient optimisation of resources, disseminating the results and promoting the developed activities.

In addition to IDEKO, the Miraged group is made up of another 4 research centres; Ikerlan (coordinator), Ceit, CTC and Idonial.