Own development model for Integrated Management of Technological Innovation.

New monitored preforming technology for composite stiffeners

It is not only lightweighting that counts in the replacement of metal with composites used for structural parts. New developments of structural parts must aim to balance production costs, the level of investment required and productivity.

At present, the manufacturing process of composite stiffeners for aircraft wing and stabilizers consists of manual or automatic lamination of carbon fibre fabrics, which yields a low productivity and the use of a different mould for each stiffener.

DANOBAT"s ADMP® (Automated-Dry-Material-Placement) is a highly productive laminating alternative, which can result in straight stiffeners that would require an automated forming process in an adaptive mould.

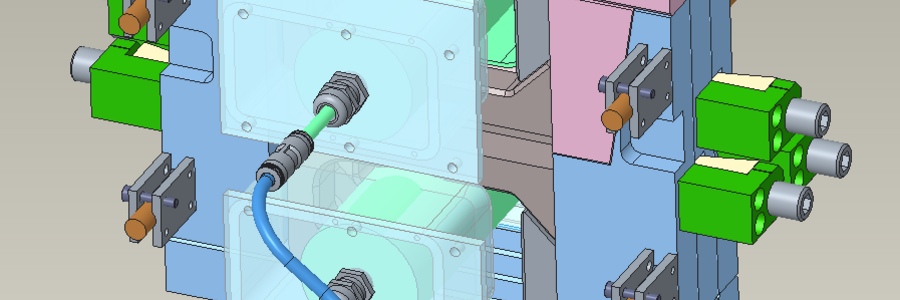

The RE-FORMA project will develop a new automated forming process based on a single universal or adaptive mould for manufacturing aeronautical stiffeners, thus eliminating all moulds required for the manufacture of each part.

The objective of this project is to develop a new manufacturing process for composite stiffeners for aeronautical structural parts with increased productivity thanks to using the DANOBAT ADMP® technology in the lamination of straight stiffeners, and subsequent forming in a single universal mould. Using ADMP® lamination would only lead to a substantial increase in productivity if the development of forming technology using a universal mould is achieved. To this end, a scale prototype will be designed and manufactured to monitor the process and to determine optimum parameters.

The work carried out in the REFORMA project will lead to a new technology for manufacturing stiffeners. DANOBAT will be able to offer the aeronautical market a completely new disruptive technology with a performance and possibilities far superior to those currently available.

The present project has a direct impact on increasing the competitiveness of automatic composite manufacturing processes, since the solution developed triples the productivity of the process and considerably reduces production costs.