Own development model for Integrated Management of Technological Innovation.

Ultra-precision machines based on low-cost and high impact solutions for the aeronautics sector.

In this project, DANOBAT and SORALUCE, with the support of IK4-IDEKO, aim to develop the technologies necessary for meeting precision requirements, in order to provide added value functions for the customer, with a machine cost lower than that of their main competitors.

The DANOBAT and SORALUCE proposal in this project is to fully develop an alternative approach to precision improvement that will allow its machines to compete on precision and costs in the highest precision applications. This approach will be based on calibration and compensation in the control of precision errors. For this, they will start with their current machines, which already stand out for their rigidity, repeatability and reliability, as well as their high precision. They will develop the tools that will add a small cost to the machine but will allow them to compete on precision with high-end machines at a lower cost.

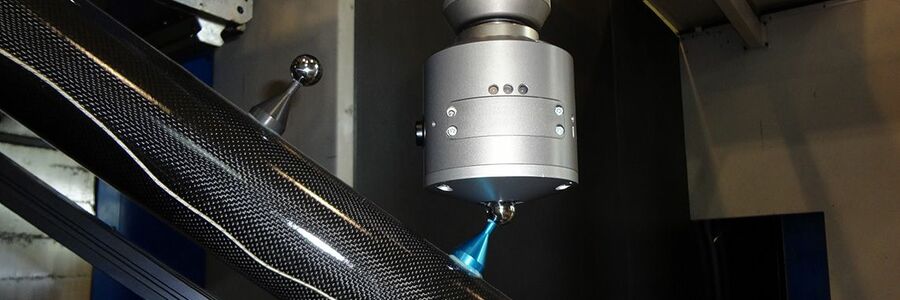

To address these needs, this project proposes the development of monitoring, verification, calibration and geometrical and thermal error compensation systems that can be integrated into the machine. This represents the main innovation with respect to the competition.

These systems will allow the maximum level of machine precision, obtained during the set-up of the machine on installation, to be maintained for the entire lifespan of the machine. No external resources are required with no added costs because the machines have fast automatic machine precision verification systems, which can be executed as required, to check the machine maintains its desired precision level. When the measurement result is unsatisfactory, the user can automatically recalibrate the machine quickly using the same means in order to recover the initial precision level. These systems also generate information during the entire life-cycle of the machine that can be used to plan maintenance processes or for the optimised design of future machines.