Own development model for Integrated Management of Technological Innovation.

Cost effective manufacturing technologies to dry carbon fibre stringers

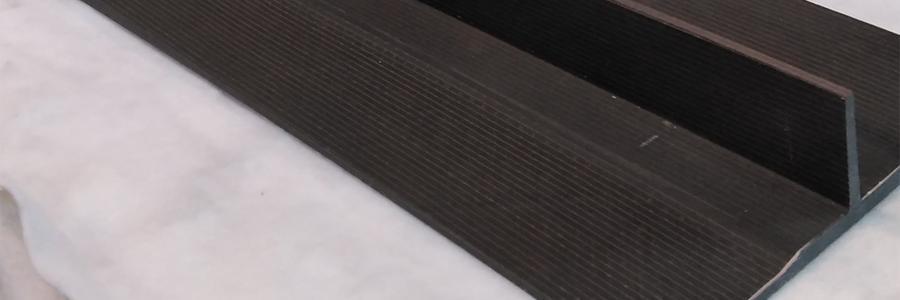

While automating the manufacture of components for the dry fibre aeronautics sector based on Danobat Composites ADMP technology, a high potential for automation was identified for the panel reinforcement stringer. This part has a small cross-section, long length and complex geometry. There are several stringers in each skin, which are usually all different in the aeronautics sector. This results in production systems with large investment in moulds and much manual work. The objective is to be able to develop a universal solution that does not require a mould for each stringer, but that uses much more versatile systems and tools so much higher automation levels can be reached.

To develop processes and test concepts that allow progress in the automated manufacture

of aeronautical sections.

Prototypes of these concepts will be built in the most appropriate way at the time.

Sections have been curved in straight Ts Good, defect-free staggers have been generated of 5 mm thickness and a 1:20 ramp. We are awaiting the infusion of the curved stringers with stagger.