Own development model for Integrated Management of Technological Innovation.

New family of grinding machines for extruded parts. Diamond dressing systems for super-abrasive grinding wheels

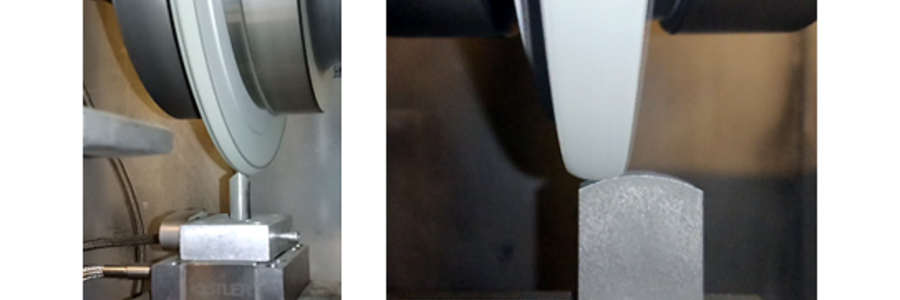

The grinding of extra hard materials requires the use of diamond wheels, mainly resin bonded. The main drawback in using this type of wheel is the difficulty of performing diamond dressing on the machine (elimination of runout, truing and dressing of grinding wheels). Today these operations are carried out off- or on- machine using high-cost, low-performance devices.

The main objective of this project is selecting, optimising and industrialising new diamond dressing processes to carry out the full grinding and dressing process on-machine in an efficient way for extra-hard parts.

The first challenge of the project is to find a solution or solutions for performing the full grinding process of coated parts on the machine, without any need to remove the grinding wheel from the machine for truing or correcting runout. Full machining process on the grinding machine.

The total time required for the diamond dressing operation, including dressing itself as well as start-up and alignment operations of the diamond dressing device, should be quite short, something between 10-15 minutes. Indeed, not only must the diamond dressing produce an optimum grinding surface of the grinding wheel to obtain quality parts, but also ensure longer intervals between dressing operations than with the currently available processes. In addition, the service life of the wear parts of the diamond dresser must be economically competitive.

Meeting specifications of part to be obtained. Specifications in terms of dimension, shape, surface finish and integrity, absence of burns and cracks, or visual defects, etc. must be met.

Diamond dressing system easily integrated on the machine. Finally, new diamond dressing processes and devices should not create a greater environmental impact than the current manufacturing methods.

The main innovations of the project have been:

• New technology to eliminate runout and perform truing on resin-coated diamond abrasive wheels on-machine using pins made of special material and new specific diamond-dressing programs, which meet all the established objectives.

• Validation and integration of ultrasonic assisted diamond-dressing technology on the machine.

• Validation of a system for monitoring and mapping grinding wheels in diamond-dressing operations with the help of acoustic sensors.