Own development model for Integrated Management of Technological Innovation.

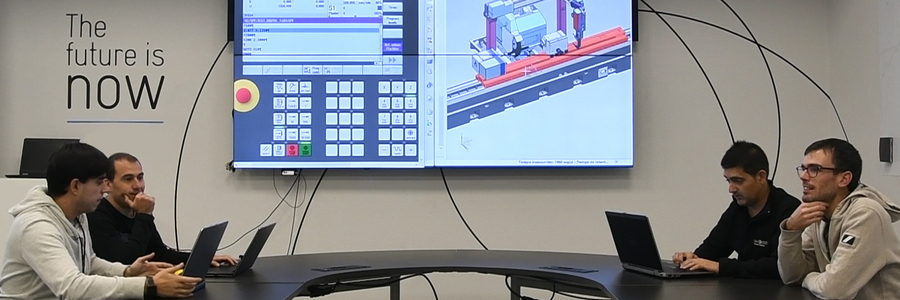

Digital Twins. Modelling and virtualisation of machine tools and manufacturing cells for virtual commissioning

In recent years, machine-tool companies have faced the technological challenge of developing fully automatic digital lines and workshops. Large projects that require the definition and improvement of manufacturing processes not only at machine level but also at automated line level. Using plant simulation tools and production flows to define the most efficient solution possible, by applying Lean Manufacturing principles, is one of the keys to these types of solutions.

Developing, analysing and validating the concept of Digital Twins and Virtual Commissioning and the benefits arising from their application in production systems, without it being necessary to have the physical equipment. This will remove the need to produce prototypes, reduce the amount of time necessary for development, and improve the quality of the machines. As well as faster adaptation in response to the customer"s specification changes.

The machine tool manufacturer will not only sell the machine but also the digital tool created as a result of this project using cutting-edge technology in connectivity, cloud computing and visual analytics in the manufacturing domain, supported in a complete solution for the industry called Industrial Cloud that is being developed and improved jointly with the IDEKO research centre. With MOVICOMS, machine tool companies can create a new product line for executing digital twins and can offer 360° digital services.