Own development model for Integrated Management of Technological Innovation.

New generation of sustainable composites for advanced manufacturing

Composites are complex materials. The reinforcement, the resin and the additives can be combined in numerous ways to provide the optimal combination of properties required for a specific application. Moreover, there are many different processing techniques available for converting the materials into parts. This means that in order to develop sustainable composites, their development must be tackled from different points of view:

- Raw materials that have the optimal characteristics for reaching the physical and mechanical properties necessary in the final part, which are sustainable and, if possible, recyclable.

- Advanced and efficient processing technologies.

- Technologies for recycling the composite and reusing materials obtained from the recycling (fibres and/or resins).

Also, the “advanced materials” and the polymer composites that belong to this category constitute the basis for innovation in a wide range of industries such as: transport, food, consumer goods, electronics, energy, health, construction, computing, telecommunications, as well as the management and recycling of waste, with the potential to allow these and other industries to become interrelated to achieve sustainable growth. In an economic context of transition to a circular economy, key challenges are presented, such as the use of resources of a biological nature and the sustainable recycling of materials, that go beyond material innovation and integrate synergy with the advanced processes and opportunities that digital technologies can offer.

AVANSITE is a collaborative scientific research project, which is developing new sustainable and recyclable composites in accordance with the needs of society and industry. There is a growing concern in society for progress to be made in the reduction of emissions and waste, in the replacement of polluting substances by other sustainable substances, in the reuse of waste and subproducts in new high added value products, in the use of natural materials, in the use of recyclable materials and products and in the responsible and efficient consumption of raw materials and energy. Materials are needed from industry that contribute to the reduction of manufacturing costs, reduce manufacturing times and energy consumption, and which allow multifunctional products to be obtained that are transformed with automatable and digitalisable technologies. From the generation of collaborative knowledge, the AVANSITE project intends to contribute to this transition, by focusing on the family of polymer composites within the field of Advanced Materials.

The main challenge that faces the AVANSITE project is that of generating scientific-technological knowledge in the field of polymer materials and composites in order to progress towards a circular economy. This will be done by addressing the development of new materials designed for obtaining functional products with advanced manufacturing technologies that make process automation and efficient resource consumption possible.

Furthermore, the project has the objective of resolving some of the challenges faced by functional polymer composites developed under the circular design concept, and will consider functionalities such as bactericide, burning behaviour and the optimisation of the composite curing-heating processes.

The AVANSITE project will yield results in the following work areas:

1. Resins:

- Optimisation of the curing process and of the transmission of UV radiation of flame-retardant bio-based resins for their use in the pultrusion process through UV curing.

2. Reinforcements:

- Definition of the methodology and characterisation of the functional fabric lamination process.

- Fireproofing of continuous glass and carbon fabrics recycled for their application in flame-retardant eco-prepregs.

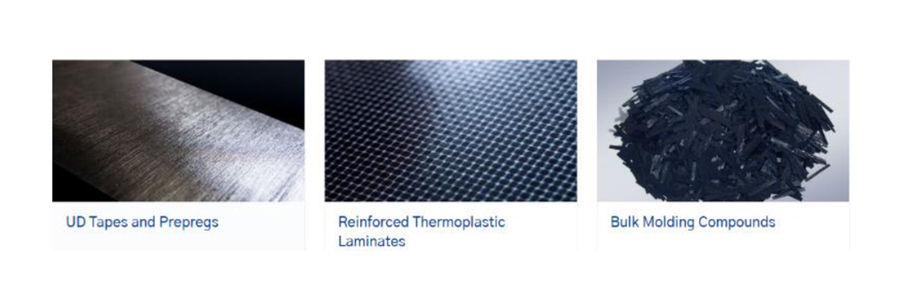

3. New sustainable composites for advanced manufacturing:

- Definition of the methodology for obtaining continuous reinforcement fibre preforms for their use in the manufacture of thin parts.

- Development of formulations for the production of prepregs and flame-retardant pultrusion and UV cured profiles.

- Study of the induction curing of adhesives and joints.