Own development model for Integrated Management of Technological Innovation.

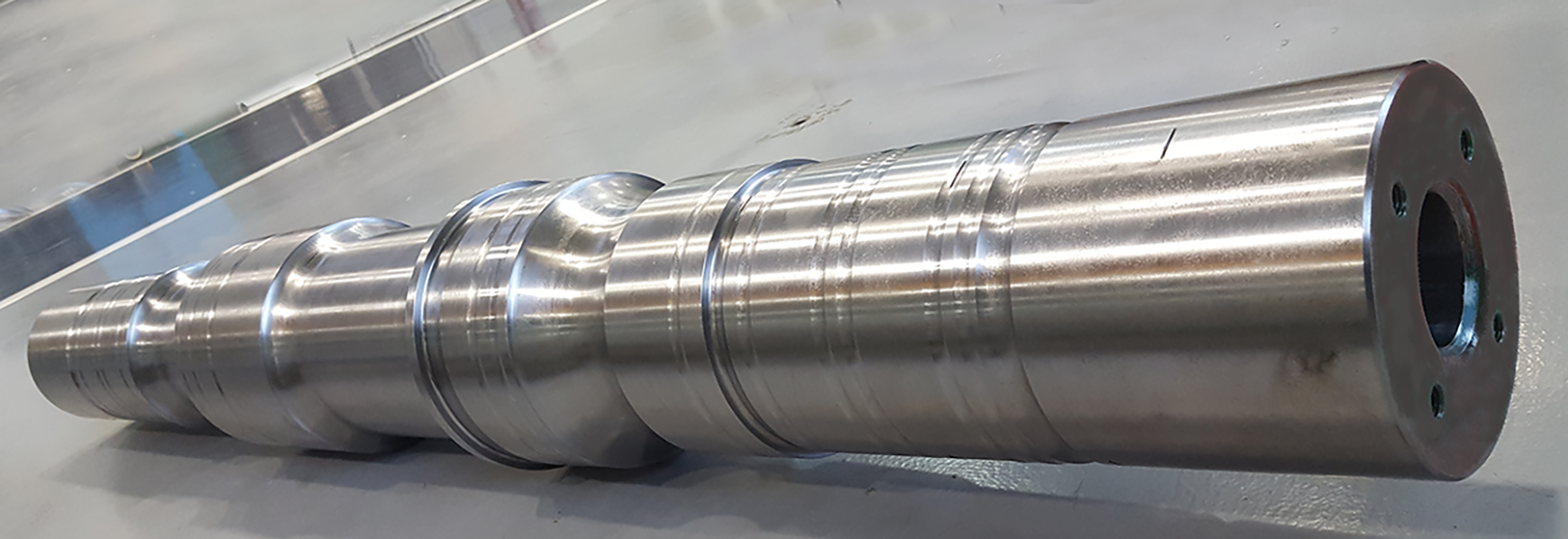

The detection of defects in trepanned railway axles during their service life

The axle is subjected to cyclic forces that can generate fatigue cracks. These cracks on reaching a critical dimension cause a catastrophic breakage in the axle that results in an accident. Therefore, the inspection of railway axles in search of defects is an essential task for ensuring proper operation.

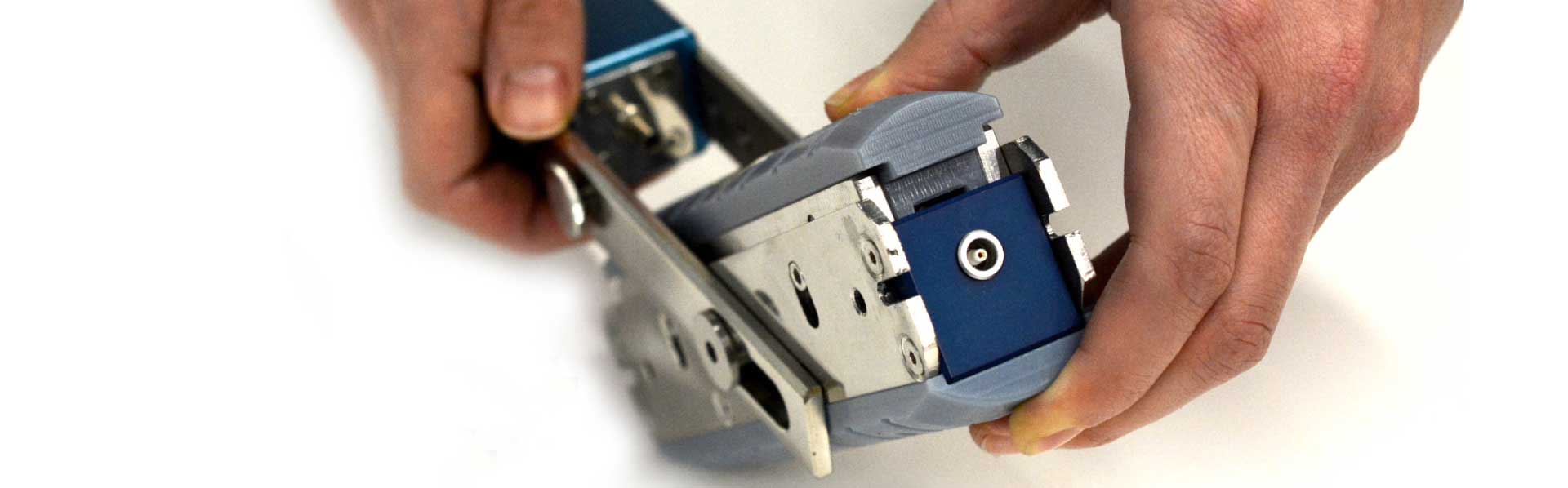

To carry out ultrasound inspection from inside the axle

When the axle is mounted on the train, the head is the easiest area to access. Normally, to access the head, only the axle box need be removed. With access to the head, to detect defects along the entire length of the axle, the trepanned hole is the best option.

A manual device has been designed that performs ultrasonic inspection from inside the trepanned hole

The manual device integrates one or two ultrasound transducers that are moved along the length of the hole, and it allows the position of the transducers to be known at all times. The device also has a preload system that maintains good contact between the ultrasound transducers and the axle. Thus, the inspection device makes it possible to obtain reliable results.