Own development model for Integrated Management of Technological Innovation.

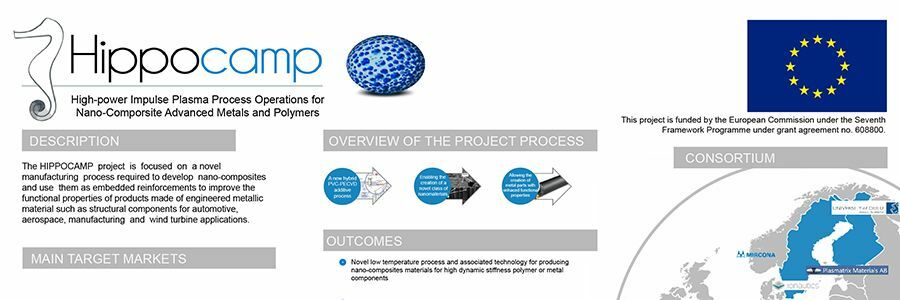

High-power Impulse Plasma Process Operations for the Creation of Advanced Metallic Parts

The use of advanced materials in strategic sectors for competitiveness of the European industry such as the aerospace, automotive and machine tool sectors is restricted because of the absence of economically efficient manufacturing processes of scalable nano-components with a low environmental footprint. In this context, the European Union has launched the Hippocamp project, which aims to develop a novel manufacturing process of nano-composites that dampen vibrations, act as reinforcement for structural parts used in those sectors and improve the functional properties

VISIT WEBSITEThe Elgoibar Centre provides data on the control of vibrations, tackles problems caused by chatter and works on the calculation of natural frequencies, on stable machining processes, sensory data processing and the analysis of dynamic behaviour of components after adding nano-composite material.

In addition, the centre also coordinates the work package related to exploitation and dissemination of the results.

Integrated framework for a cost-effective and ease of Repair, Renovation and Re-use of machine tools within modern factory

Plug and Produce Components for Optimum Dynamic performance Manufacturing Systems

Development of an integral platform for collecting and processing large volumes of data to support strategic decision-making

New aerospace advanced cost effective materials and rapid manufacturing technologies