Own development model for Integrated Management of Technological Innovation.

Minimise the impact that chips or dust from high-risk machining operators

The use of composites has increased significantly at a global level in different industrial sectors such as the aeronautical, wind power and transport sectors mainly. That is why the European Commission decided to finance the project ASPIRATE in order to minimise the impact that chips or dust from high-risk machining operators may have on the operator"s health such as during machining processes of some composite materials.

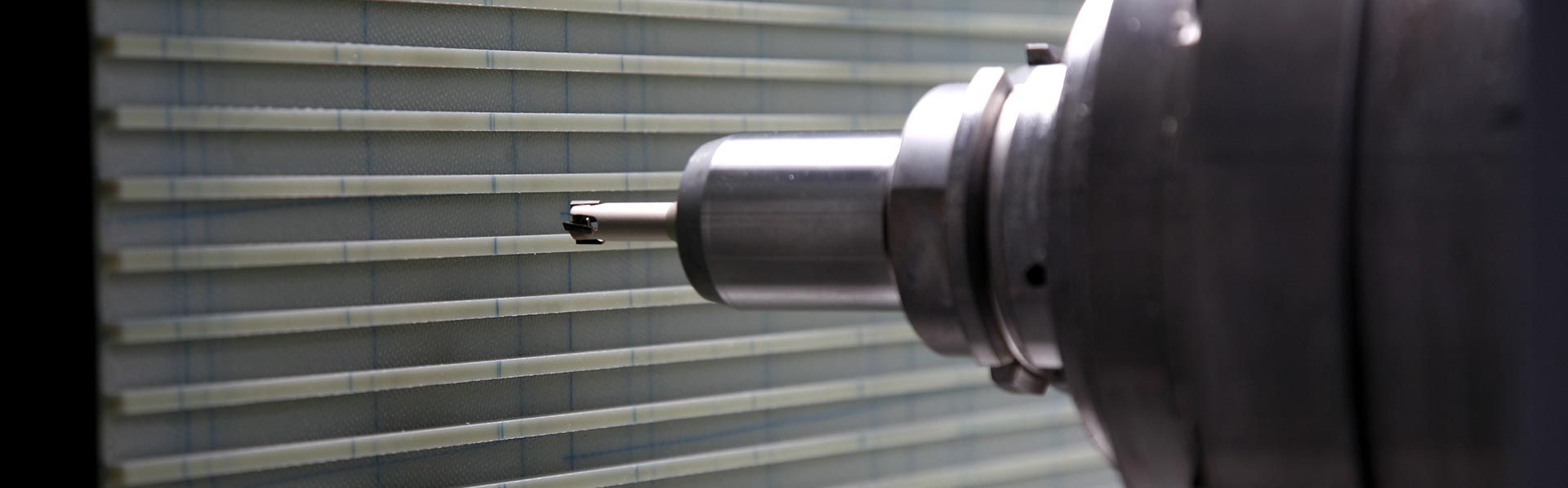

Innovative technology for machining of CFRP and GFRP based on the internal extraction of the produced chip

The main object of the ASPIRATE project is focused on the development of an innovative technology for machining of CFRP and GFRP based on the internal extraction of the produced chip and dust particles through the whole machining system (cutting tool, tool holder, spindle), avoiding all the external devices and suction pumps used nowadays.

Cleaner and safer work areas

The following innovations have resulted from the project:

1) a new process for machining GFRP/CFRP,

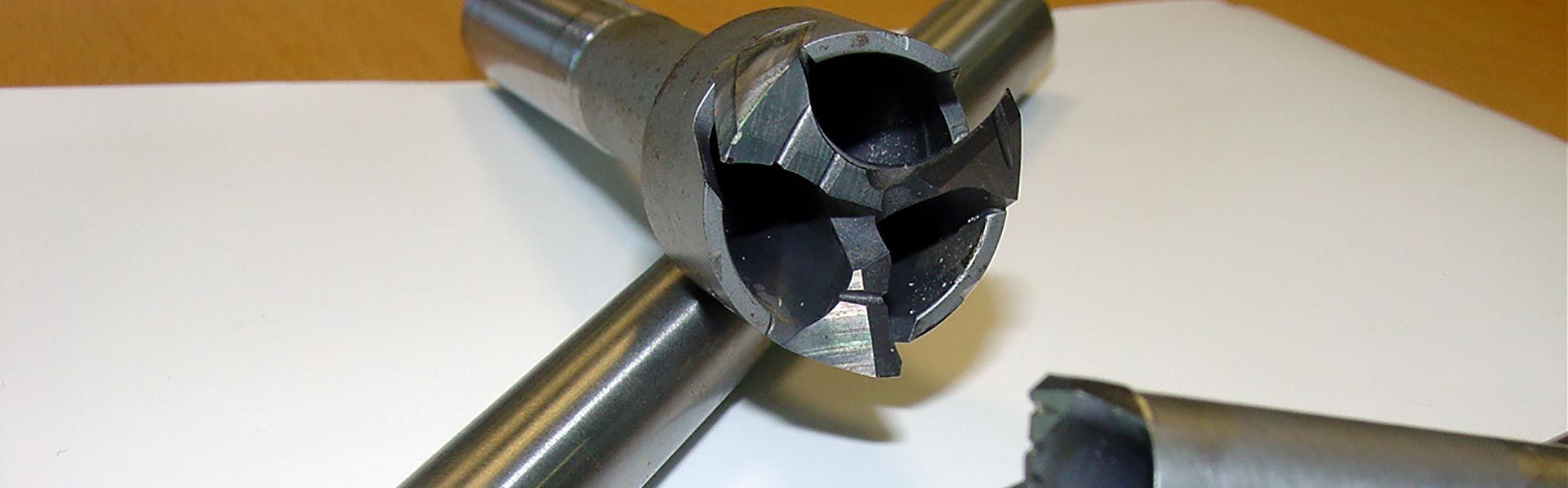

2) tools have been modified to allow the removal of chips; new requirements were established so that the new technology can be used on both the machine and equipment,

3) PCD tools with a serrated tooth have been designed, developed and tested for the removal of the chips, reaching excellent results both in machine efficiency and in swarf removal.

Advantages obtained with this new process:

- cleaner and safer work areas,

- clean and dry parts, no further cleaning required,

- easy subsequent processing of dust and chips,

- compatible with standardised clamping, e.g. HSK,

- very simple system as no additional equipment is required.

Aeronautical, wind power and transport sectors.

As such, the research line Machining and Production Systems improved the flexibility of the process and obtained a completely clean machining process and eliminated the health risks for the machine operator.